Oil Aeration is Dangerous

We can help

SERVICES

Diagnosis

Leverag the 30+ years we've spent understanding the phenomenon of aeration and mastering the formulation science necessary to solve your issues. Solving aeration problems requires both an understanding of the oil you use and your equipment's setup and operating conditions. We partner with you to identify factors leading to aeration in your system and to gain key insights about your system that are necessary for the development of a formulated solution.

Formulated Solutions

Our customizable chemistry is tailored to enhance or replenish your specific oil in the conditions it’s exposed to in your system. All you have to do is send us a sample of your oil and we’ll handle the rest. Based on our testing and understanding of your system’s operation, we will develop a formulated top treat you can add to your oil that will mitigate the harmful effects of foam and entrained air.

Implementation

We’ll provide you with support to ensure our product is incorporated into your system in a way that maximizes its performance. Every system’s setup and operating conditions are different and we’ll make sure you know how to properly add our technology to get the most benefit. We’re here to help you every step of the way!

Aeration

Lifecycle

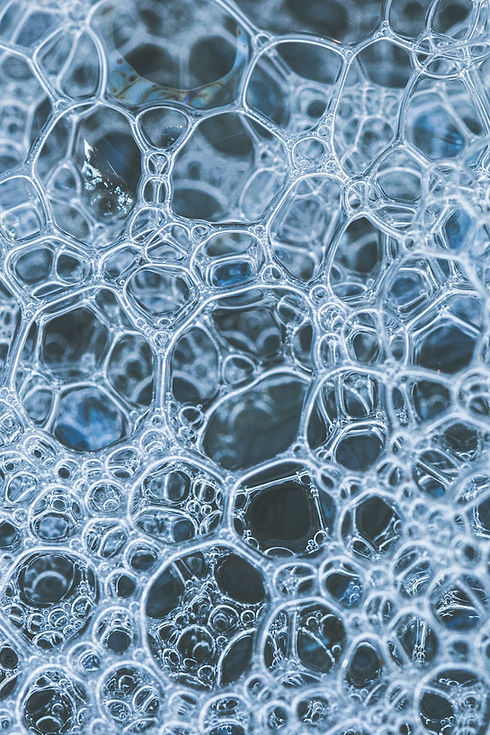

Some level of air is naturally occurring in oil. However, this is typically not the reason for aeration problems. Instead, it’s the incorporation of air into the oil while it’s being used in industrial applications. This can happen for a variety of reasons (e.g. leaks and cracks in pressurized equipment, diffusion through the oil surface, and turbulence caused by pumps). Once in the oil, air exists as three main types; the most obvious of which is foam. This is a visible layer of air bubbles floating on the oil surface supported by thin layers of oil coating the bubble surfaces. What’s less noticeable is the entrained and dissolved air circulating in your system. The difference between these is related to the size of the air bubble. Air pockets suspended below the surface of the oil, and separated by larger volumes of oil is known as entrained air. This entrained air may become dissolved air if pressure of the system is high enough.

Symptoms

Some symptoms are more obvious than others. Obviously, if you’re experiencing the presence of a lot of foam, you are experiencing signs of air entrainment in your oil system. Other symptoms include:

-

An overflow of fluid into areas of your system and facility it should not be in

-

Faster oxidation of the oil

-

Decreased oil pressure

-

Downtime due to a loss of oil pressure

-

Increased noise pollution from system equipment

-

Increased vibration in system equipment

-

Damaged hardware

-

Loss in the effectiveness of pump control

-

A loss of lubricant supply in pressurized systems

-

Erratic measurements of diagnostic sensors

-

A decrease or loss in power or efficiency

-

Hotter lubricant operating temperatures or loss in the ability to control oil temperature

Causes

Along with understanding your system and the symptoms you are experiencing, we need to assess the likely things affecting aeration in your system so we can devise a technology for your specific application.

The incorporation and buildup of air is related to a variety of factors including:

-

The chemical components of the oil being used

-

Physical properties of the oil

-

The operating temperature of the oil throughout the system

-

Contaminants getting into the oil

-

Leaks or cracks in pressurized systems

-

Hardware the oil is processed through, such as pumps and hydraulic equipment

-

The oil filtration system and frequency of filter changes

-

Frequency of oil changes

-

Sump size

-

Any downtime when your system is not running

-

Inherent propensity of bubbles to rise to the oil surface

Our Technology

We understand the frustrations associated with air getting entrained in oil and its inability to escape. This is why we’ve become leaders in diagnosing aeration problems and providing customized top treat technologies compatible with oils in the market. We know it’s important to keep equipment moving which is why our products are designed to be easily added to your existing system to enhance or replenish your oils aeration performance.

Depending on the types and severity of your symptoms, the equipment design you are using, and the operating conditions your oil is exposed to, our technology is designed to:

-

Reduce air trapped in the oil

-

Reduce downtime

-

Eliminate premature oil changes

-

Prevent equipment failure

-

Stabilize oil pressure

-

Reduce erratic diagnostic sensor signals

-

Prevent overflow of oil caused by air incorporation

-

Reduce noise & vibration issues

CONTACT

We’re ready to help! We know people are busy these days, so leave the hard work of figuring out how to solve your aeration problems to us. We’ll partner with you to understand your system, learn about the symptoms you are experiencing, develop a technology to mitigate air in your system, and work with you to ensure it’s incorporated in your oil in a way that maximizes its benefits.